MAGNETICALLY IMPELLED ARC BUTT WELDING

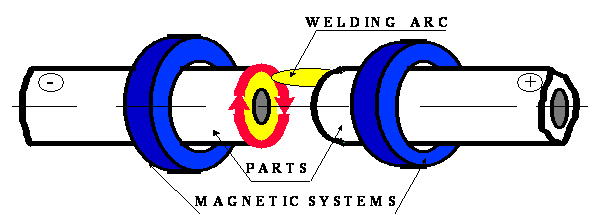

Principle of MIAB welding

MIAB welding is a forge welding process that relies on an electric arc to generate necessary heating to melt the surfaces being welded.

How MIAB welding works?

Welding arc rotate in the gap between tubes due to the presence of external magnetic field generated with permanent or electromagnets.

The maximum Linear Speed of the arc movement is 870 km/hour.

The spinning arc in combination with thermal conductivity of the welded metal creates very uniform heating at the joint.

On completion of welding, the welded parts are rapidly brought under pressure.

Applications of MIAB welding

Butt welding of thin-walled tubes

Butt and T-butt welding of automobile parts

Butt welding of thick-walled tubes

Butt welding of solid parts

Tube to plate welding

Tube to flange welding

“This machine tool based process is attractive to the mass production industries because of the short cycle times and reproducible quality.”

Optional features of MIAB

Two welds can be carried out simultaneously on a double ended machine

Mobile machines are available.

Retractable electromagnetic coils and field profile control for easy loading and unloading of work.

Can be configured for automatic flash removal.

Mobile MIAB machines can be used on site and allow transmission pipelines to be welded with potential savings due to improved productivity over other arc welding processes.

MIAB welding machines for pipes

Download Advanced Welding Solutions